Hot stamping, also called foil stamping or foil blocking, is a process in which foil is transferred to a product surface (or “substrate”) using high temperatures and pressure. Hot stamping is used to decorate and mark countless products, from stationary to books to health and beauty packaging to food and beverage cartons.

It is important to note that the foils used in hot foil stamping are not always metallic. The pigments may be shiny or matte and come in a wide variety of colors and patterns. They can be pearlescent, holographic, or even clear.

Key Takeaways

- Hot stamping (AKA foil stamping) uses heat, pressure, and photoetched and/or engraved dies to transfer a foil design to a substrate (such as paper, cartons, labels, or plastics).

- Hot foil stamping is used to mark and decorate thousands upon thousands of everyday products.

- Most hot stamping dies are made from copper, brass, or magnesium.

- Copper and brass dies are extremely durable, they transfer heat well, and they can produce incredible textures and minute details.

- Magnesium dies can hold fine details and are used for some of the same hot stamping applications as copper, but they are not nearly as strong or durable. When they are used, it is typically for cost savings on short runs.

- Universal Engraving’s copper and brass dies are world-renowned for their artistry and precision. Each can last for over one million impressions!

What Is the Hot Stamping Process?

Hot stamping is accomplished with the use of hot stamping dies, into which the lettering, pattern, logo, image or other design to be transferred is engraved and/or photoetched.

- The die is mounted in a press and heated, with the product to be stamped beneath it. The foil is placed between the two.

- When the hot stamping die is pressed down, the combination of heat and pressure transfer the foil to the substrate. Because the design stands up slightly from the die surface, it comes into contact with the foil while the rest of the die (called the “relieved area”) does not. This means only the desired design transfers to the substrate.

- The product now bears a clean, crisp hot foil stamped design.

Hot stamping can be accomplished using a sheet fed press, or a narrow web press that utilizes either a flatbed station or rotary tooling/dies.

What Are Some of the Benefits of Hot Foil Stamping?

The main benefit of foil stamping is its visual appeal. It gives packaging or products that extra touch of richness and quality that helps them stand out. It sends the message that the product is a step above—something special, intriguing and valuable.

The foils used in hot stamping are opaque, meaning they don’t change color regardless of the substrate on which they are applied. This makes it possible to create a dramatic contrast with a light-colored design or lettering on a dark background.

It is possible to achieve different textures and light-catching designs using Universal Engraving’s Unifraxion® hot foil stamping dies. These striking effects can help products stand out on store shelves amid rows of competition.

Hot stamping is also an exceptionally versatile process. With the right die, it can be used on a wide variety of substrates, including paper, vinyl, leather and plastic.

What Are the Main Types of Hot Stamping Dies?

Using the right die for the job can make all the difference in the quality and consistency of the impression over multiple runs, as well as production costs. The choice will depend on the product or substrate composition, the length of the production run, the quality or detail needed in the impression, the hot stamping machine or press used, and the surface features of the product to be stamped. An expert die manufacturer, such as Universal Engraving, can help you determine the best die for your specific application.

At Universal Engraving, we specialize in sheet fed dies, narrow web flatbed dies, and rotary cylinders for hot stamping applications. Our dies are crafted of either copper or brass, which we recommend for their durability, consistent results, long-term cost-effectiveness, and ability to produce the finest designs.

Magnesium Hot Stamping Dies

Photoetched or photoengraved magnesium dies are typically lower in initial cost than copper and are used for some of the same hot stamping applications. Magnesium can hold fine detail, though not as well as copper due to its comparative softness. This softness also means magnesium doesn’t have the same durability and longevity over long runs as copper or brass. When magnesium dies are used, it is typically for cost savings on short production runs.

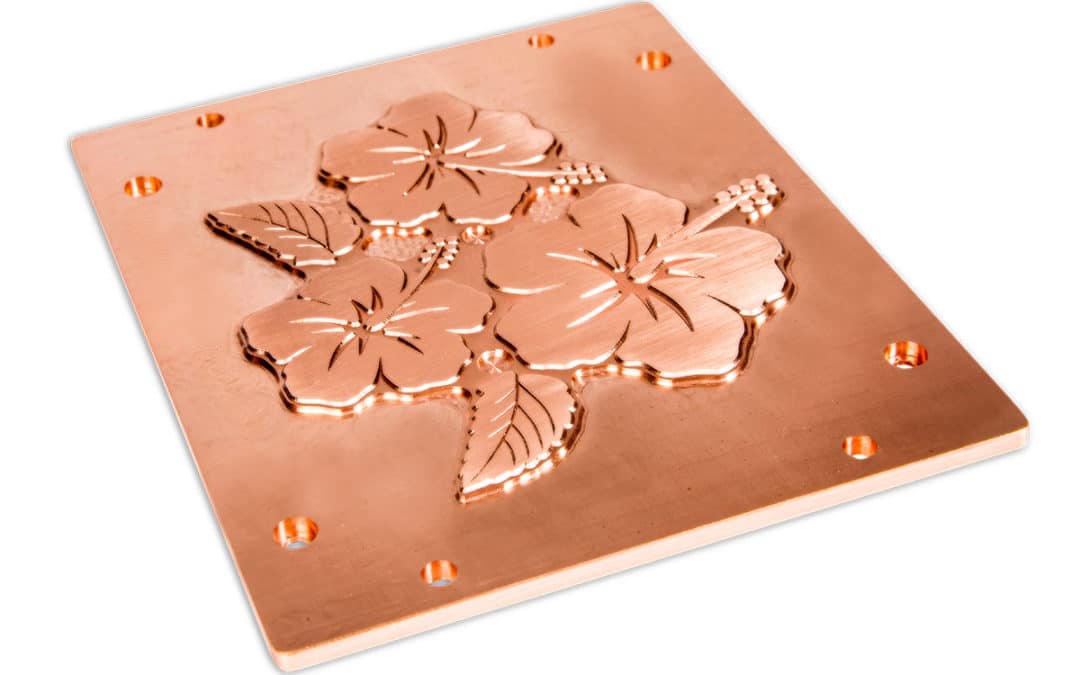

Copper Hot Stamping Dies

Copper dies are photoetched and can be used on a variety of substrates. They are capable of holding finite detail. Copper wears much better than softer metals such as magnesium and isn’t susceptible to pitting or image damage.

Copper dies are the best choice for recuperating heat, making them one of the most effective foil stamping dies. Copper also has exceptional hardness, meaning that it doesn’t “pit” or “nick” as easily as other etched or engraved metals such as magnesium. At Universal Engraving, our copper dies are tough enough to withstand over one million impressions, as long as they are used and cared for properly.

Copper can be used to create hot stamping dies for sheet fed and narrow web flatbed.

Brass Hot Stamping Dies

Brass is known for its exceptional workability, strength and durability. It can be engraved to the tightest tolerances and used to produce unrivaled engraved effects. Brass is often used to create multi-level (or combination) dies that foil stamp and emboss in one pass.

Brass dies from Universal Engraving are world-renowned for their beauty, artistry and precision. With proper care and use, each one is capable of performing over one million impressions. Whether you are looking for intricate detail or realistic depth, brass engraved dies from Universal Engraving set the standard for excellence.

Partner With Universal Engraving

Universal Engraving is one of the world’s leading manufacturers of foil stamping dies and die lock-up technology. Our copper and brass dies are known for their durability, quality and longevity. Contact us today for hot stamping dies that will help you make the best possible impression!