Thankfully, solutions and technological advances can help circumvent many of these issues by streamlining workflows and processes, reducing costs of fulfillment, and creating sophisticated and dynamic packaging using copper and brass foil stamping and embossing dies.

Challenge #1: Increased Demand for Packaging With Pick-Up Value From Brand Owners

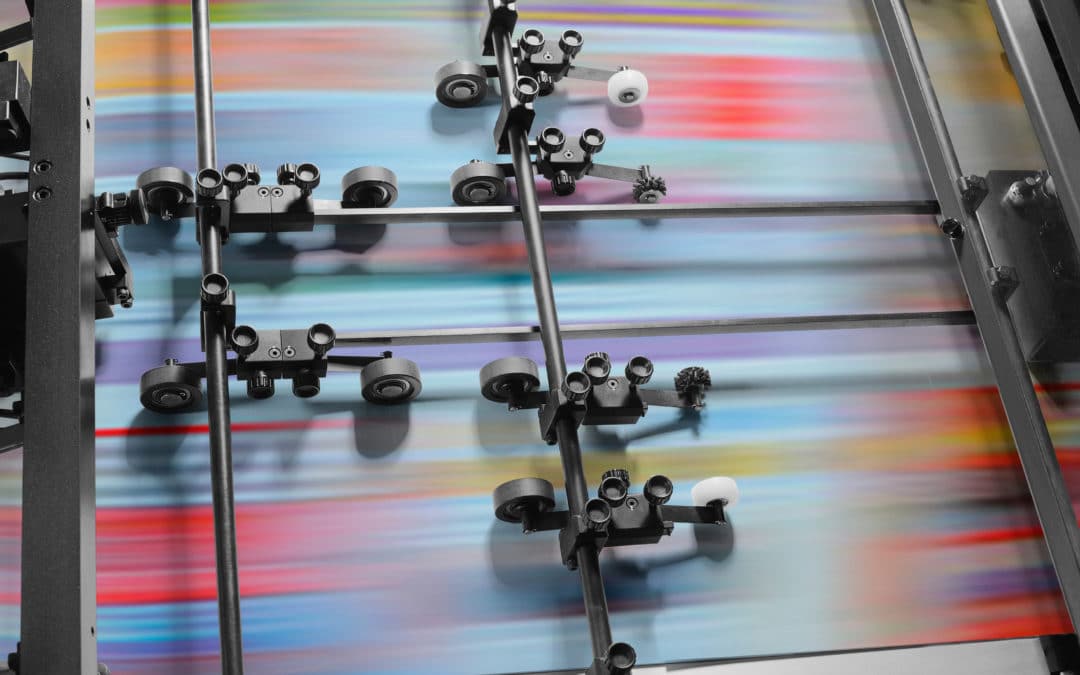

With many industries becoming more competitive, there is an increased emphasis on packaging presentation. The challenge here is that many printing companies that specialize in packaging are struggling to keep up with the demand for more dynamic packaging design. For many companies that rely heavily on packaging to catch a customer’s eye, traditional printed labels are just not enough.

The latest technology gives clients exactly what they are looking for. Printers should be able to accommodate and offer a variety of solutions, including the following:

- More complex designs

- Increased customization options like embossed textures and designs

- The ability to print on different types of materials

Two suggestions? Refractive dies, such as UE’s Unifraxion® dies, bring new light, depth, and movement to package designs. This unique graphic alternative uses metallic hot stamping foil and fine engraved line patterns to impart definition to images. Textured dies turn ordinary packaging into a tactile masterpiece. Textures can be used with hot stamping foil, metalized paper/board, or incorporated into an embossing die.

Challenge #2: Managing Workflow & Productivity

Brand owners not only want dynamic packaging—they want it faster than ever before. Naturally, this increased demand leads to a higher cost of fulfillment. However, brands do not seem to increase their prices to reflect this.

This has an indirect effect on packaging designers and printers. Not wanting to raise retail prices, brand owners are looking to printing companies to keep their prices low. Automated workflow systems can help by streamlining workflow and processes. Lower cost of fulfillment leads to lower prices. Lower prices are what brand owners are looking for.

One way to overcome this challenge is to find automated workflow solutions that work for your business. This could include keeping track of employee productivity, monitoring machinery uptime, and overseeing projects from beginning to end. When utilized correctly, digital workflow solutions can increase productivity and reduce costs.

Additionally, Universal Engraving offers revolutionary decorative enhancement solutions that streamline production and allow for better management of workflow.

- The UniLock-Up® die lock-up system takes the guesswork out of registration and reduces press set-up time on a traditional honeycomb chase up to 75%

- The SpeedChase® offers the fastest changeover system in the industry and significant savings on the cost of dies.

Challenge #3: Lack of Manpower

Finding professionals who are well-versed in the packaging printing industry has long been challenging. However, 2020 and the COVID-19 pandemic have made finding and retaining good help more difficult than ever.

The automation, smart machinery, and digital solutions we’ve discussed can go a long way in helping you do more with fewer bodies. However, don’t overlook the importance of strong outsourcing relationships and vendor partnerships.

One of those vendors is Universal Engraving. Our products can help you address issues like reduced manpower and expensive downtime.

Case in point, take a look at our advanced SpeedChase and UniLock-Up technology. Our UniLock-Up systems ensure proper die registration, and they increase precision and efficiency. Our SpeedChase systems allow for easier lock-up, lower costs, and reduced downtimes.

Proper utilization of our lock-up systems helps automate production and lower the amount of staff you need on hand, while also creating higher-quality finished products.

Partner with Universal Engraving!

In addition to our lock-up technology, Universal Engraving expertly crafts foil stamping and embossing dies made from copper and brass. These engraved dies are useful in creating beautiful, eye-catching product packaging. By utilizing our foil stamping and embossing dies, you can increase your client’s pick-up value, giving you an edge over the competition.

Take a look at our collection of hot stamping and embossing sheet-fed dies!